Did you know Nike lost just under £100 million in the early 2000s because of inventory mistakes? Their inventory management system was riddled with data errors which led to inaccurate forecasting. The end result? Product demand stayed high but the number of products being manufactured wasn’t being matched.

It’s safe to say Nike was able to bounce back quite comfortably, but it’s clear to see that no business is safe from the damaging impacts of poor inventory management decisions. Today, we’ll look at some inventory mistakes in everyday management and offer some suggestions on how to avoid them.

Here we will cover 6 inventory mistakes that can be avoided and potentially save your business time and money in the future:

- Don’t leave inventory checks so long

- Have an organised warehouse/stockroom

- Provide the required training to staff

- Understand surplus stock and how to get rid of it

- Ordering too little stock

- Lack of automation

1. Stop leaving your inventory checks so long

Inventory checks or stock takes are arduous jobs, but the longer they’re left, the longer you’re going to spend rectifying mistakes. Performing bimonthly stock takes can be the difference between spending a few hours correcting a few misplaced stock items now, or days correcting hundreds in a years’ time.

Pushing all your inventory jobs into a single event can create a mountain of work for you and your team. The warehouse or stockroom must be prepped, and all problems detected with staff and managers at the ready. The longer it’s left, the more likely your yearly stock take will turn into a dreaded day by all involved. In that time, products may have been damaged, lost, or even stolen – and nobody will know until the following year. Unless you’re only tracking a very small inventory, there are many few companies that can get away with performing stock checks once a year, or before a peak season. Interested in speeding up and increasing the accuracy of your stock checks? Barcode scanning is your answer.

Combine regular stock checks, with perpetual inventory (PI), and you have a recipe for inventory success.

What is perpetual inventory?

Perpetual inventory is a practice that monitors inventory changes in real-time without the need for physical inventory checks. All stock information is gathered from established input devices such as point-of-sale or HHT systems so that users can access real-time data to improve their inventory strategies.

PI systems will flag up fast-moving stock locations for counting based on when they were last counted, versus how often they are being used. Combining this method with regular spot checks means your business is doing all it can to keep on top of your counts.

Advancements in inventory management systems have made integrating with PI systems a more viable and practical option. Moreover, many cloud-based ERP software systems offer built-in POS and HHT systems to provide retailers the tools to easily execute a perpetual inventory method.

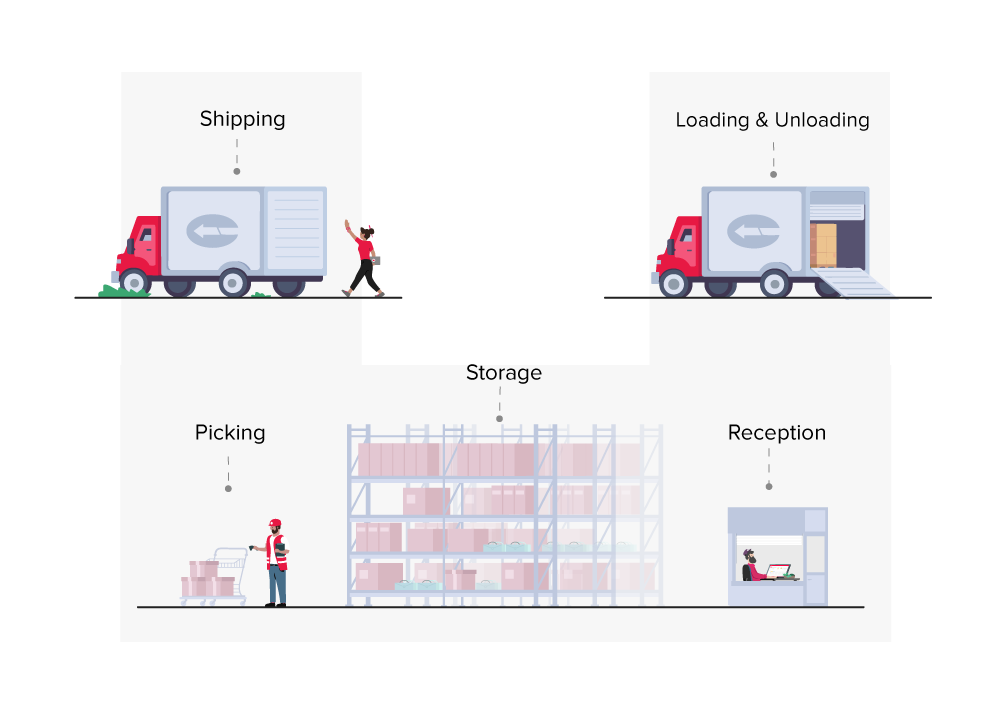

2. Badly laid out warehouse or stock room

Apply the same level of care to your stockroom or warehouse as you would your main office – especially when it comes to layout. Keep stock in a logical order with dynamic and static stock being stored in separate areas.

Dynamic storage vs. static storage

Also known as forward pick, is an area of your warehouse where orders are being consistently picked for fulfilment. This area might include multiple types of racking to reduce overall picking time. By supporting such a “picking journey”, you’re allowing your pickers to get an order fulfilled as quickly as possible. Static storage will include stock with fixed locations, overspill of your dynamic storage area, as well as some possible empty spaces.

Once you have your warehouse layout optimised, keep it clean, organised, with a system in place for every process – especially when it comes to your inventory. Maximising your warehouse space and storing stock is as easy as you choose to make it. If you have messy storage habits, you can likely expect some messy inventory blunders. Experiencing a sudden surge in orders is also no excuse for storing stock where you can find the space. Busy or not, every item or bundle should be kept in a set area. Without well-thought-out labelling and storage, it’s hard to keep a warehouse organised. Of course, make sure your best-sellers are accessible, but make sure you also don’t end up with a corner of neglected stock that doesn’t have a home.

3. Lack of adequate training leading to inventory mistakes

It goes without saying there are huge risks in setting an untrained member of staff loose on your inventory management system. For those with little experience, new inventory management systems aren’t always easy to pick up straight away – even for those who have used inventory tools before. Every system operates differently. This can lead to discrepancies on stock descriptions, stock levels, accounts, and the accurate status of your orders (to name just a few). Always ensure your staff have had adequate training on any automated inventory systems in the business.

Once your staff are effectively trained on a good ERP software system, you can expect to see the following:

- Manual tasks become automated

- Smarter workflows are implemented throughout the business

- Efficiency of staff increases from increase automation

- Increase in accuracy and accessibility of data

- Improved procurement management

- Improved relationships with vendors and suppliers

- Boosted cash flow from improved inventory handling and faster order processing

- Too much inventory = higher overheads + Too little inventory = longer fulfilment times – any good inventory management system will prevent both of these issues.

- Effective forecasting and more informed purchasing

- Increase transparency throughout the business

Prioritise communication between teams

Just as inadequate training can prevent you from reaching your business’s full inventory potential, the same goes for a lack of communication between teams. Sales teams’ need to be aware of stock availability to avoid overselling. Your customer service team needs to be aware of order issues to keep your customers in the loop, and your accounts department needs to be aware of any misplaced items or issues with suppliers. Failure to communicate will nearly always result in a hit on sales and customer retention.

4. Surplus or access stock

As well as being wasteful and taking up precious shelf space, surplus stock ties up capital and stops you from reinvesting back into your business. Over ordering on stock is one of the easiest inventory mistakes to make – especially if you’re hopping on a trend or ordering in bulk from suppliers – but it’s one that’s hard to undo when you’re left trying to shift excess stock.

Supplier lead time

Your supplier lead time directly affects the level of control you have over access stock. The longer your lead time, the more stock you’re left with. Longer lead times also make deliveries more unpredictable and force a company to rely heavily on demand forecasts to make orders.

Turnaround time

As well as your supplier lead time, and depending on your business model, there’s a handful of other lead times to take into consideration to maximise your stock control:

Customer lead time: how long it takes to fulfil a customer’s order.

Material lead time: the amount of time it takes to receive materials from a supplier.

Cumulative lead time: the amount of time it takes to manufacture a product from start to finish and assemble it for delivery.

Once all these times have been taken into consideration, be that through your own formula, or being processed through an ERP software system, you should be left with an informed decision.

Sales performance

The performance of your individual stock items should also give you a good understanding of appropriate purchasing levels. Using an inventory management system will break down your best sellers, low-performing stock items, as well as bundles of stock items.

Movement of your items

Always pay attention to your sales and inventory data – all the answers about how much stock is appropriate to order lies within there. Keep an eye on how the individual stock items or groups bringing in consistent revenue, as well as your most successful promotions. From here, you should be able to make solid purchasing decisions and avoid as much waste as possible.

Always pay attention to your sales and inventory data – all the answers about how much stock is appropriate to order lies within there. Keep an eye on how the individual stock items or groups bringing in consistent revenue, as well as your most successful promotions. From here, you should be able to make solid purchasing decisions and avoid as much waste as possible.

5. Ordering too little stock

Surplus stock is costly, but not being able to fulfil orders will damage customer retention, trust, as well as revenue. Without proper forecasting, businesses cannot make informed decisions when it comes to matching stock to demand. Most inventory management tools will provide you the option to set safe levels against your different stock items. These safe levels will ensure reordering software applications are letting your business know when, and how many items you need to reorder to keep up with demand.

Backorder system

Backordering tools will also provide your business the ability to have stock automatically assigned to back-ordered items, the moment goods get booked in from your suppliers. Using a simple back-order system, your business can quickly see your backorder requirements, as well as making quick purchase orders to fulfil demand exactly. Existing stock therefore gets reallocated to more urgent orders – and you’re balancing exactly the right amount of stock.

Businesses opting for a just-in-time inventory method also will always run the risk of stock-outs and disappointed customers. Whilst this method can work for some, we only recommend established businesses with reliable 3PL providers and suppliers opt for this practice.

6. Lack of automation

Automation has the potential to transform any business with an inventory, and help remove common inventory mistakes. A fully integrated and automated stock system will help you manage, organize, and track material purchases, product sales, and other inventory processes.

A lack, or no automation within a business can cause fundamental losses because of errors, stock-outs, overstocks and time wasted. Maintaining the right inventory balance is no simple task. As we discussed earlier, automation or ERP software enables you to track low stock levels and identify the reorder points for every product. This automated process helps you with efficient order management, ultimately leading to cost-saving.

Curious to find out more ways of optimising your stock control and avoid inventory mistakes? We have a series of articles offering a closer look at how your business can achieve the perfect inventory management strategy.