At some point, you will have probably noticed a little alphanumerical code printed on the product labels in your favourite store. This humble code SKU code might seem insignificant at first, but it plays a significant role in effective inventory management and sales maximisation.

In this article, we’ll cover what SKU numbers are, why they’re essential for your business, how to create an effective SKU architecture, and how to get the most out of them when tracking inventory, gaining sales insights, and increasing customer satisfaction.

What is a SKU?

A SKU (stock-keeping unit) is an alphanumeric code assigned to products and/or variants in a retailer’s catalogue and is used to track a business’ inventory internally. Generally speaking, SKU numbers are about eight to twelve characters long, with each character or group of characters corresponding to a unique characteristic of the product it represents.

SKUs are not universal; they are exclusive to your business and tailored to your needs. Each SKU in your inventory should be unique to help you identify, track and manage all the individual products in your product catalogue. You can print a label that displays the SKU in the alphanumeric form and as a barcode for scanning purposes.

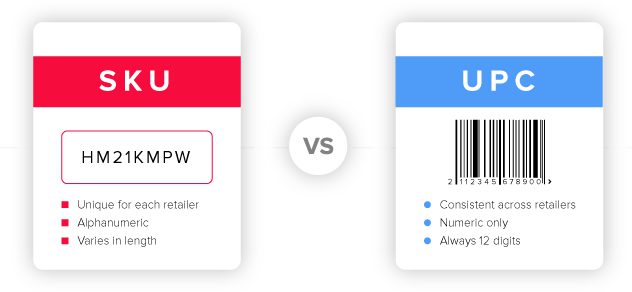

Stock Keeping Units vs Universal Product Codes

One point of confusion with SKU numbers is that they often get mixed with universal product codes (UPCs). This is an easy mistake to make, as both are typically located on a product’s price tag.

SKUs are not regulated or standardised. Companies create SKUs internally to track inventory. Even if a company receives items from a vendor, it has a choice of maintaining the vendor’s SKU or creating its own. As a result, SKUs for even the exact same product may vary among businesses.

In contrast, universal product codes consist of twelve numeric digits that are uniquely assigned to each product. Therefore, UPSs for the same products are identical regardless of which business is selling the items. UPCs are regulated and administered by an international not-for-profit organisation called GS1 that develops and maintains global standards for business communication. They are unique for every product in the world, so if your company has developed a new product, you’ll have to apply for a GS1 company prefix so you will be able to assign a UPS to that product.

UPCs are placed on products by the manufacturer. SKUs, on the other hand, are determined by the retailer. Another significant difference between the two is that UPC numbers are a random assortment of numbers. In contrast, every character in a SKU number is purposefully chosen and represents a specific characteristic of its assigned product.

Should you use SKUs or UPCs?

UPCs, are practically mandatory for wholesalers since they are best for product tracking across multiple businesses. On the other hand, SKUs are best for direct-to-consumer (D2C) retailers. Suppose you aren’t selling your products to other businesses, and your inventory is only for internal use within your company. In that case, you can avoid the expense of licensing UPCs for your inventory and simply use an internal SKU architecture.

Nevertheless, it is worth mentioning that several online marketplaces like Amazon, eBay, or Google Shopping require you to have a UPC to sell products on their platform.

Similarly, if you are direct to consumer company but you’re purchasing your products from a wholesaler instead of selling your own products, using SKUs could prevent competitors from matching advertised prices and steal your customers. Shoppers cannot easily view the same product at other sellers based on the SKU alone.

Some small D2C business owners may decide to use UPC numbers instead of setting up their own SKU numbers. However, this approach takes away many of the advantages of having a system tailored specifically to your business’s needs.

How to create your SKUs

Retailers use SKUs to track their inventory and sales. But each retailer won’t be monitoring the same things. As a result, the first step in creating an effective SKU architecture is to carefully examine your business’ specific needs, sales priorities, and customer profile.

When creating an UPC, there is a precise procedure; its 12 numbers are broken into the company prefix, item reference number, and a check digit. On the other hand, creating an SKU is entirely up to the business owner since the purpose of the SKU is to manage inventory internally.

SKUs can be made with any combination of numbers, letters, and special characters. Nevertheless, it’s crucial to create a standard format to follow. Consider what attributes are to be decoded in your SKUs numbers and letters and determine how you plan to map them and be consistent in the format. Having a specific structure in place will make the generation of SKUs for new products an easy, straightforward task.

Tips for creating SKU numbers

- Only include relevant data. Remember: the goal is to help employees understand what product an SKU is referring to as fast as possible.

- Try to limit your SKU between eight and 12 characters. The length of your SKU will depend on the number and variety of products you sell. Still, similar to point no.1, include enough information in your SKUs but try to keep them short enough so that information can be quickly extracted.

- Keep the same format for each SKU. Good SKUs follow a standardised formula across the company.

- Go from broad to narrow. Brand-product type-colour-size, for example.

- Use letters in addition to numbers. Letters can be more easily coded to have meaning, and it will be easier for your employees to remember.

- Prevent ambiguities. Avoid letters that look like numbers like the letter “O” and the number “0,” or the letter “l” and the number “1.”

- Use special characters with caution. Separating the different sections of your SKU with dashes (-) is fine but be careful when using special characters like “/”, “>”, “*”, etc. They will not only make it harder for employees to remember SKUs but may result in errors when you import them into a spreadsheet.

- Align SKUs across your sales channels. Make sure you only have one SKU for each product variant across every channel you sell on.

How to get the most out of your SKUs

The primary purpose of SKUs is to manage your inventory internally. Nevertheless, a good SKU architecture with the correct implementation can positively impact other areas of your business, like future sales and demand forecasting, or help personalising which products are recommended to customers in-store and online.

Accurately track inventory and improve customer experience

A great SKU architecture will ensure that each item will be easier to locate and associate with other catalogue management data, such as stock levels and manufacturer or supplier information. Use your SKU numbers to track a product’s availability and overall stock levels across multiple retail stores and sales channels.

Scanning the status and activity of each SKU will make it easier to determine when more stock needs to be ordered and avoid reaching critical stock levels and backorders. By minimising the number of out-of-stock items, you can establish yourself as a reliable source that customers can count on to have the products they need at any given time and boost your brand loyalty.

But even if the product a customer wants is out of stock, your sales reps can suggest alternative products with similar characteristics based on their SKU number. Moreover, you can easily create a “other products you may like” section in each product page on your online shop by automatically including product suggestions that share similar characteristics in their SKUs as the main product.

SKUs will also help your warehouse staff using barcode scanners to pick and pack orders quicker and more accurately. Combine that with a shipping management platform like ShipTheory that can entirely automate your fulfilment process and increase customer satisfaction by shipping your products to them minutes after an order is complete.

Forecast sales accurately and make the most out of your best-selling products

By using SKUs in your business, you can more strategically, and in-depth analyse the volume and progression over time of both demand and sales for each product in your inventory. That will allow you to make smarter and more precise decisions regarding your store’s inventory and marketing budget.

SKUs can help you quickly identify items that don’t sell well, avoid accumulating products that are not profitable or find new ways to get stagnant stock moving. Similarly, by identifying which products of your catalogue are your best sellers at any given time of the year, you can create attractive marketing campaigns that will help you promote and sell those products even faster.

In essence, by using SKUs, you can keep track of your products in real-time and better understand the needs of your business.

Final thoughts

SKU numbers are a great way of managing inventory systematically that fits your business needs precisely. Associating each product with a specific alphanumerical code that reflects its unique characteristics allows you to make smarter business decisions. Whether that’s inventory decisions, making it easier for your sales team to recommend products that share similar traits, shipping your orders faster, boosting sales, or keeping customers happy.

But before you start drafting your SKU architecture, you need to know your business and customers’ needs in depth. Only then your SKU architecture will allow you to manage your inventory efficiently and maximise sales.